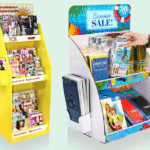

How to Turn Your Pop-Up Cardboard Stand Design into a Finished Product

By Shenzhen Topwon Group Co.,Ltd

Dec 14, 2025

Topwon frequently receives inquiries like this: clients say they already have their own design drafts and ask if we can produce items based on those drawings. Of course we can—in fact, it only takes three simple steps to turn your ideas into reality:

Example: I have a design for a pop-up cardboard stand I would like to have made.

Analyze and Refine Core Requirements

Primary Requirement: Paper folding display stand (pop-up cardboard stand)

Core Prerequisite: Existing design blueprint for the display stand

Final Goal: Convert the design blueprint into a physical finished product

Three-Step Method: Turning Your Design into a Real Display Stand Product

Finalize the Design:

Ensure the design is both visually appealing and manufacturable to avoid rework later.

Define core parameters: Clearly specify length, width, and height dimensions. Allow 1-2cm bleed margin to prevent cutting errors.

Simplify Complex Structures: Successful products often prioritize simplicity. Avoid overly intricate processes. Where practical, streamline the structure to meet functional requirements.

Select Corrugated Paper Based on Load Capacity: Different weight capacities require varying thicknesses and grades of corrugated paper. This necessitates structural analysis calculations and ensuring sufficient load-bearing capacity.

Proofing Based on Design Drafts

All custom paper display stands require prototyping before mass production to ensure the final product matches the design intent. Note that printed colors differ from screen displays. Simply requesting “exact color matching” is unrealistic for manufacturers.

Mass Production :

Once the sample is approved mass production commences. However, mass-produced items cannot be identical to the sample. All relevant parameters will fall within acceptable tolerance ranges. It’s worth noting that clients often perceive a slight difference in paper thickness between mass-produced items and the sample. This perception is inaccurate. Mass-produced items undergo tighter compression during assembly, facilitating easier transportation and reducing shipping costs. Quality control measures, including inspections and spot checks, are strictly enforced to meet specifications—such as sharp printing, clean trims, and complete accessories.

In summary, requests to produce paper display stands based on existing design drafts are common. This scenario represents custom manufacturing. However, we don’t simply replicate any design provided by the client without modification, as this could lead to significant issues. The original design may contain logical inconsistencies or impractical elements. As a source manufacturer with over a decade of experience in custom display rack design and production, we must communicate with clients based on practical considerations and accumulated expertise. Only after finalizing the design through this process can we proceed step-by-step with the production of paper display racks.

Trusted by These Featured Clients