Common Size of Beverage Display Racks

By Shenzhen Topwon Group Co.,Ltd

Jun 02, 2025

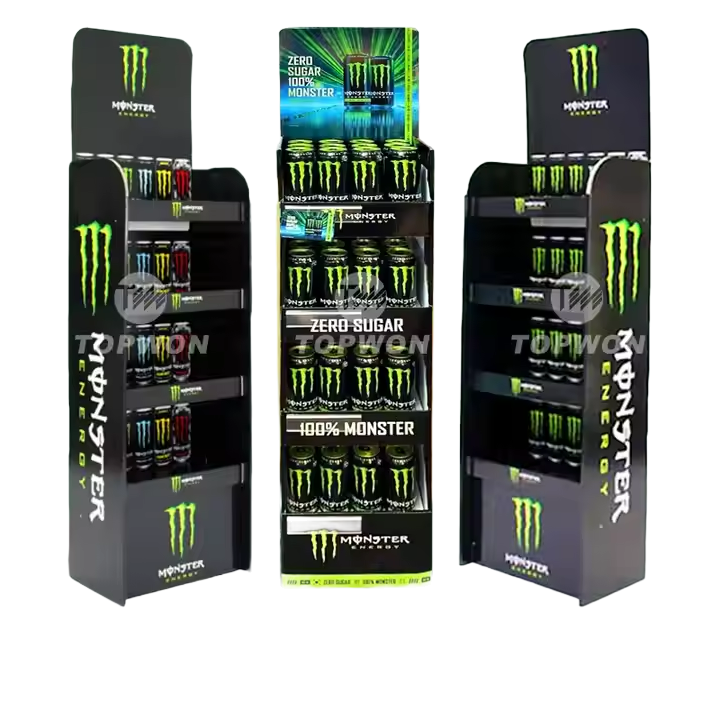

Here is the detailed size table of corrugated cardboard floor beverage display racks. We should determine the number of layers and load-bearing capacity, and further refine parameters by combining them with practical application scenarios.

Floor-standing Corrugated Beverage Display Rack Size, Layers & Load-bearing Table

| Type | Length (cm) | Width (cm) | Height (cm) | Layers | Load per Layer (kg) | Total Load (kg) | Actual Example Size (cm) | Suitable Beverage Types |

|---|---|---|---|---|---|---|---|---|

| Small | 30-45 | 20-30 | 100-130 | 3-4 | 5-8 | 15-25 | 35×25×120 (3 Layers) | Canned beverages (330ml-500ml) |

| Medium | 45-60 | 30-40 | 130-150 | 4-5 | 8-12 | 30-50 | 45×30×140 (4 Layers) | Bottled beverages (500ml-1L), boxed |

| Large | 60-80 | 40-50 | 150-180 | 5-6 | 12-15 | 60-80 | 60×40×160 (5 Layers) | Large bottled beverages (1.5L-2L), cases |

Key Parameter Explanations

1. Logic of Layer Design

- Small display racks: Taking 120cm height as an example, the layer spacing is about 30-40cm, suitable for 3-4 layers of display, often used for vertical display of single-specification beverages (such as stacked cola cans).

- Medium display racks: When setting 4 layers at 140cm height, the layer spacing is about 35cm, compatible with upright placement of bottled beverages (e.g., mineral water bottles are about 25cm high, with 10cm top space reserved).

- Large display racks: 5 layers designed at 160cm height, with the bottom layer about 20cm from the ground (to prevent moisture), and 30cm layer spacing, suitable for large bottled beverages or case stacking (e.g., 2L juice case is about 28cm high).

2. Influencing Factors of Load-bearing Capacity

- Corrugated material:

- 3-ply corrugated paper (A/B/C flute): Load per layer is about 5-8kg, suitable for small display racks.

- 5-ply corrugated paper (AB/BC flute): Load per layer can reach 10-15kg, often used for medium and large display racks.

- Structural reinforcement design:

- Adding “well”-shaped support strips (3-5cm thick) at the bottom can increase the bottom layer load by 20%-30%.

- Bond double-layer corrugated paper (1–1.5 cm thick) to the columns to prevent tilting from multi-layer loading.

- Load-bearing test cases:

- Medium 4-layer display rack (5-ply corrugated paper): Each layer places 12 bottles of 500ml mineral water (about 0.5kg per bottle), with a total load of 24kg and no obvious structural deformation.

3. Scene Adaptation and Load-bearing Suggestions

Beverage Display Racks Size and parameters table

| Beverage Type | Weight per Bottle (kg) | Quantity per Layer | Suggested Layers/Load |

|---|---|---|---|

| 330ml canned beverage | Approximately 0.35 | 15-20 cans | 3-4 layers/Total load ≤25kg |

| 500ml bottled water | Approximately 0.5 | 8-12 bottles | 4-5 layers/Total load ≤50kg |

| 1.5L bottled beverage | Approximately 1.5 | 4-6 bottles | 3-4 layers/Total load ≤40kg |

| Beverage case (24 cans) | Approximately 8-10 | 1-2 cases | Bottom layer single load/≥15kg |

Notes

- Load balancing: Avoid concentrated stacking of heavy objects on a single layer (e.g., only placing on one side of the bottom layer), and symmetric display is recommended.

- Dynamic load: Pay attention to instantaneous load during handling or restocking (such as impact force when placing cases), and light layered placement is recommended.

- Material testing: Before customization, suppliers can be required to provide a “compressive strength test report” (e.g., in accordance with GB/T 6546-1998 standards) to ensure actual load-bearing meets standards.

In short, these are the common Beverage Display Racks Sizes, but usually beverage displays are customized, including size, appearance, printing and many other aspects.

Trusted by These Featured Clients