What is lamination?

By Shenzhen Topwon Group Co.,Ltd

Nov 02, 2025

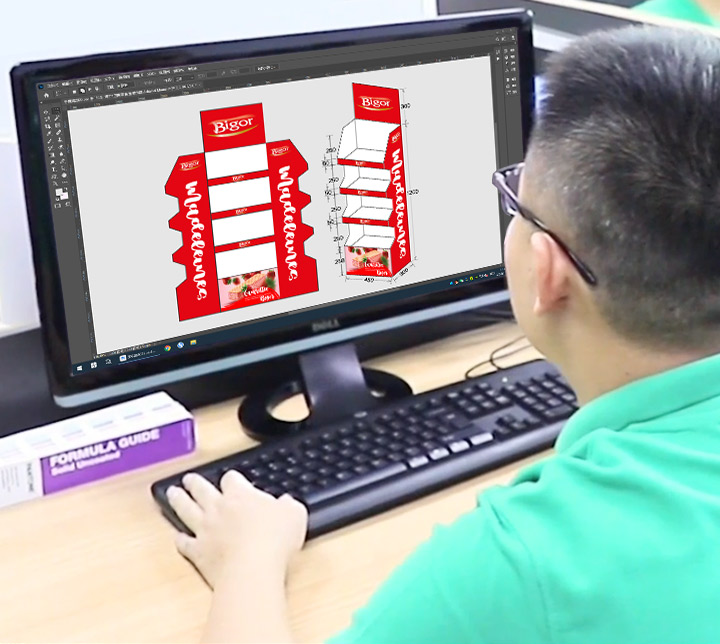

Laminating is a process used across numerous industries. Today, Topwon focuses on laminating within the corrugated cardboard display stand sector. Let’s explore what laminating entails:

Corrugated cardboard serves as the core material for manufacturing display stands, and it comes in various types. Common corrugated cardboard classifications include:

- A Flute: Highest flute height (approx. 4.5-5mm)

- B Flute: Lowest flute height (approx. 2.5-3mm)

- C Flute: Flute height between A and B (approx. 3.5-4mm)

- E Flute: Extremely fine flute height (approx. 1.1-2mm)

How are these different types of corrugated paper produced? Laminating is one of the common processes.

What does laminating do?

Simply put, it involves applying adhesive to multiple layers of paper, stacking them together, and then using heat pressing to firmly bond all layers. This creates corrugated paper that can be directly used to produce corrugated display stands.

What are the main steps in lamination?

Adhesive coating->stacking->hot pressing

Additionally, there’s a newer lamination technique: litho lamination.

Litho Lamination

Also known as lithographic lamination, this process enables printing high-resolution images. This aligns perfectly with the needs of the advertising display industry, making it a popular laminating method for corrugated cardboard displays today.

In summary, laminating is the process of bonding different paper layers together through coating, stacking, and heat pressing. The currently popular litho laminating enables printing of high-quality, high-resolution images, making it highly suitable for the advertising industry. Consequently, it is widely adopted in the POP displays sector.

Trusted by These Featured Clients